The use of copper (I) catalysts is known for the reaction of ammonia with aryl halides to form the corresponding anilines. Ligands such as proline are known to enhance the catalytic activity of the copper (I) catalyst (see for example Figure 1 in https://www.mdpi.com/2073-4344/12/8/911). An advantage of copper catalysts is the lower cost relative to other metal catalysts.

However, in most cases, only aryl bromides and iodides are applicable for the Cu-catalyzed ammonolysis reaction. Aryl chlorides are quite inert toward this type of Cu-catalyzed reaction. In addition, polar solvents such as DMSO or DMF are often used for these reactions (see Table 1 in https://www.mdpi.com/2073-4344/12/8/911).

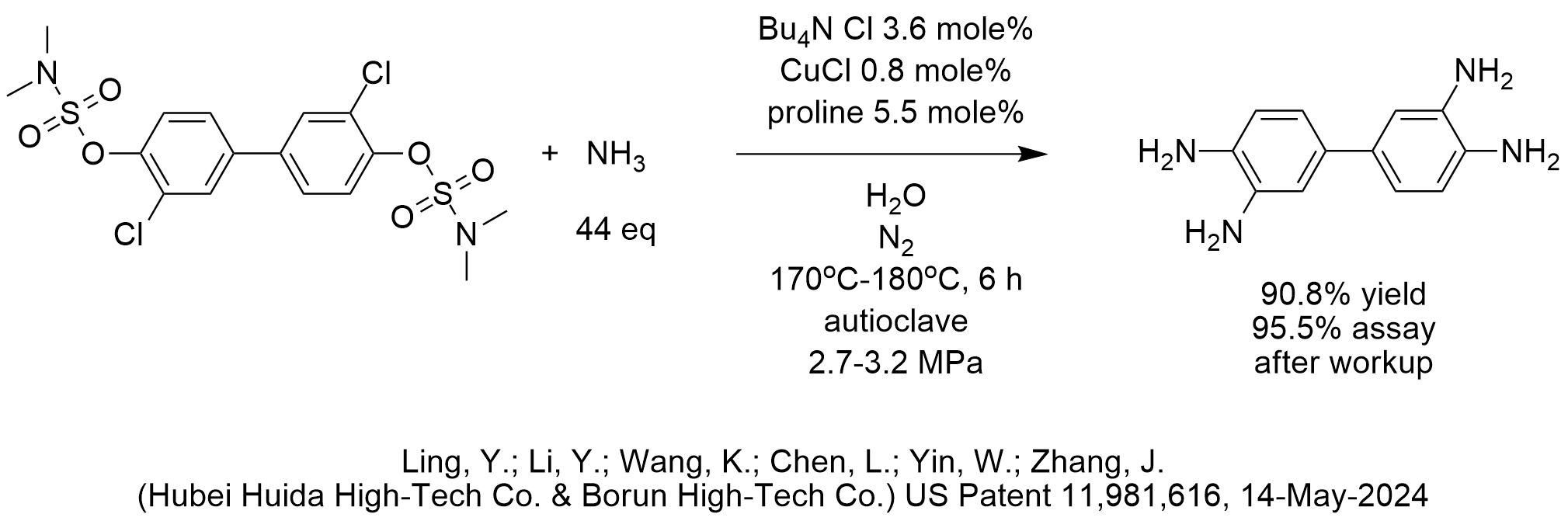

The inventors found that the combination of proline with Cu(I) catalyst and the addition of a phase-transfer catalyst, such as tetrabutylammonium bromide, tetrabutylammonium chloride, triethylbenzylammonium bromide, triethylbenzylammonium chloride, tetrapropylammonium bromide, or an imidazoline quaternary ammonium salt, provides several advantages such as:

- The amount of the cuprous salt can be greatly reduced under the premise of efficiently promoting the smooth progress of the amino substitution reaction, so that the high-concentration metal salt wastewater is effectively reduced, pollution of “three kinds of wastes” is reduced, the method is more friendly to the ecological environment, and the wastewater treatment cost is reduced.

- Less expensive aryl chlorides can be used without having to use aryl bromides or iodides.

- Polar solvents such as DMSO or DMF are not required.

- The ammonolysis reaction can be carried out under milder conditions, at a temperature of 170-180° C. and a pressure of 2.5-3.5 Mpa for 5-10 h.

About Marc Halpern

Dr. Halpern is founder and president of PTC Organics, Inc., the only company dedicated exclusively to developing low-cost high-performance green chemistry processes for the manufacture of organic chemicals using Phase Transfer Catalysis. Dr. Halpern has innovated PTC breakthroughs for pharmaceuticals, agrochemicals, petrochemicals, monomers, polymers, flavors & fragrances, dyes & pigments and solvents. Dr. Halpern has provided PTC services on-site at more than 260 industrial process R&D departments in 37 countries and has helped chemical companies save > $200 million. Dr. Halpern co-authored five books including the best-selling “Phase-Transfer Catalysis: Fundamentals, Applications and Industrial Perspectives” and has presented the 2-day course “Practical Phase-Transfer Catalysis” at 50 locations in the US, Europe and Asia.

Dr. Halpern founded the journal “Industrial Phase-Transfer Catalysis” and “The PTC Tip of the Month” enjoyed by 2,100 qualified subscribers, now beyond 130 issues. In 2014, Dr. Halpern is celebrating his 30th year in the chemical industry, including serving as a process chemist at Dow Chemical, a supervisor of process chemistry at ICI, Director of R&D at Sybron Chemicals and founder and president of PTC Organics Inc. (15 years) and PTC Communications Inc. (20 years). Dr. Halpern also co-founded PTC Interface Inc. in 1989 and PTC Value Recovery Inc. in 1999. His academic breakthroughs include the PTC pKa Guidelines, the q-value for quat accessibility and he has achieved industrial PTC breakthroughs for a dozen strong base reactions as well as esterifications, transesterifications, epoxidations and chloromethylations plus contributed to more than 100 other industrial PTC process development projects.

Dr. Halpern has dedicated his adult life to his family and to phase-transfer catalysis (in that order!).