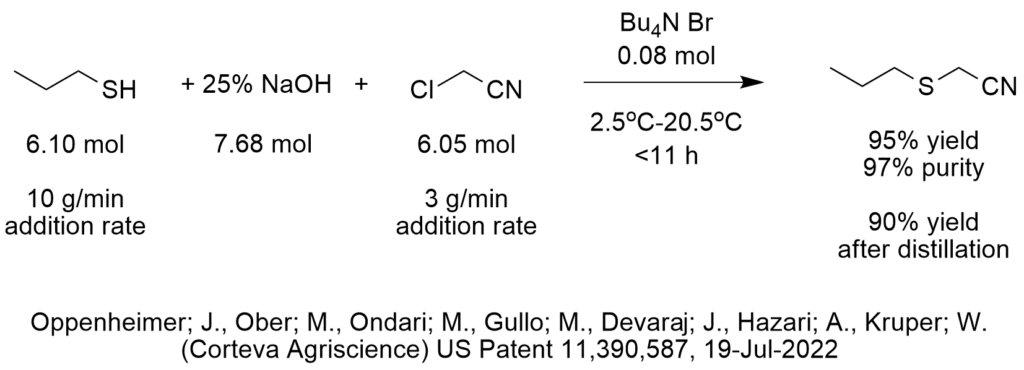

A solvent-free PTC S-alkylation was reported this month by Corteva, the agrochemical company formed in 2019 by Dow and DuPont (apparently in Dow’s Zionsville, IN facility).

Solvent-free PTC conditions are chosen when the reaction can be performed at a temperature at which at least one of the reactants and the product are liquids at the reaction temperature and there are no stirring challenges. This is the case for the reaction shown in the diagram. The use of 25% NaOH (as opposed to more dilute or more concentrated aqueous NaOH) likely assured two liquid phases even after liberation of the chloride leaving group when taking into account the solubility of NaCl in water. If there are no solids, stirring should not be a problem. Even when solids are present in solid-liquid solvent-free PTC systems, slurries are often stirrable.

Advantages of solvent-free phase-transfer catalysis include high reactor volume efficiency, faster kinetics for PTC I-Reactions and avoiding the need to store, handle, recover and separate the solvent form the product.

The inventors chose to perform the neutralization by adding the propane thiol to the aqueous NaOH, presumably at a rate to control the exotherm. The phase-transfer catalyst was present during the neutralization, though probably not yet needed until the S-alkylation. The neutralization was likely instantaneous based on the relative pKa’s of the thiol and water (conjugate acid of hydroxide), though the inventors stirred the thiol, base and TBAB for 1 h 45 min before adding the chloroacetonitrile, again presumably at a rate to control the exotherm.

It is possible that the bromide of the TBAB co-catalyzed the reaction by forming bromoacetonitrile in-situ, though the thiolate nucleophile is likely more nucleophilic than the bromide.

The important point in this reaction is that solvent-free PTC conditions are often advantageous when the at least one reactant and the product are liquid at the reaction temperature and there are no stirring problems.

About half the phase-transfer catalysis processes developed by PTC Organics are solvent-free (liquid-liquid, solid-liquid or liquid-liquid-solid). Now contact Marc Halpern of PTC Organics to explore collaboration when your company can benefit from more than four decades of experience and specialized expertise in solid-liquid PTC systems.