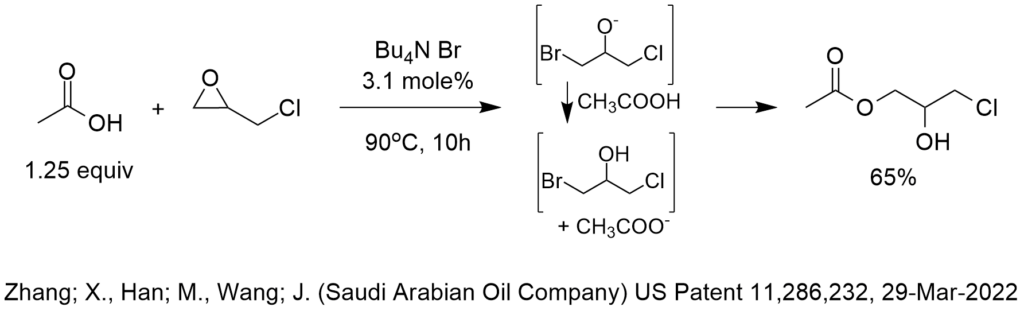

The procedure for the reaction shown in the diagram does not contain any base (first step in Example 2 in the patent). The reaction is performed by simply mixing acetic acid, epichlorohydrin, catalytic tetrabutylammonium bromide and heating to 90 C for 10 hours. The procedure does not specify if there is more than phase before starting the reaction but we assume that it is a homogenous single phase.

The procedure for the reaction shown in the diagram does not contain any base (first step in Example 2 in the patent). The reaction is performed by simply mixing acetic acid, epichlorohydrin, catalytic tetrabutylammonium bromide and heating to 90 C for 10 hours. The procedure does not specify if there is more than phase before starting the reaction but we assume that it is a homogenous single phase.

There doesn’t appear to be a leaving group or salt that accumulates and the bromide is just a catalyst. The only role of the tetrabutylammonium appears to be to solubilize the bromide in the organic phase.

The mechanism is assumed to consist of the bromide attacking the epichlorohydrin to form the short lived bromochloropropoxide anion (tetrabutylammonium as the cation), which is so basic that it would rip off the proton for the acidic acetic acid. This would form tetrabutylammonium acetate and the acetate should be a good nucleophile that would displace the bromide (better leaving group than chloride) to form 3-chloro-2-hydroxypropyl acetate. TBAB is regenerated for another catalytic cycle upon the liberation of the bromide.

If this speculated mechanism is correct, then this in not a phase-transfer catalysis reaction. It is simply a reaction that is catalytic with respect to the bromide ion and the role of the tetrabutylammonium cation is to keep the bromide in the organic reaction phase.

We welcome comments by our readers if you have better ideas about what is occurring in this reaction.

By the way, the excess acetic acid appears to be removed from the reaction mixture product by water wash during workup. However, we would be surprised if the TBAB is very soluble in the aqueous phase during workup since they used saturated NaCl for the water wash. When one wants to removed TBAB from a reaction mixture during workup, it is best to use water with no ionic strength to avoid salting out of the TBAB from the aqueous phase.

When your company needs expertise in removing quat salts from reaction mixtures during workup, now contact Marc Halpern of PTC Organics to benefit from highly specialized expert consulting for separating the phase-transfer catalyst from the product as we teach in detail in our 2-day course “Industrial Phase-Transfer Catalysis.”