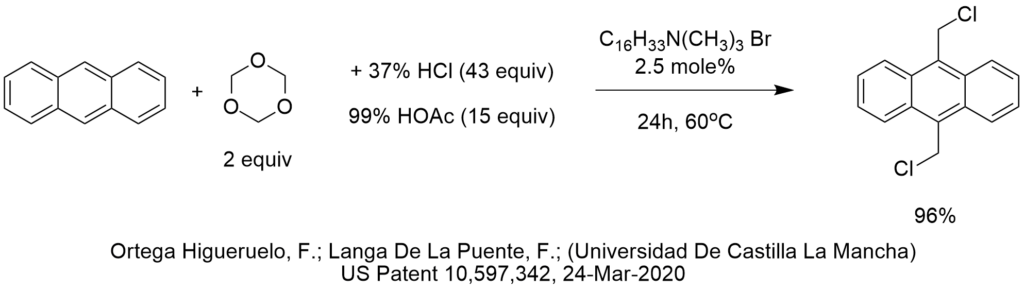

This patent describes the chloromethylation of anthracene (only anthracene). Before commenting on this patent, it is important to be aware that chloromethylation reactions often produce as a byproduct the highly toxic compound bischloromethylmethyl ether which has a history of being so hazardous and lethal that it is addressed in United States Code of Federal Regulations and OSHA standards that include special personal protective equipment, ventilation, personal exposure monitoring and other safety requirements. Please do not repeat the reaction condition shown in this patent without fully written hazardous operations analysis performed by licensed professionals including industrial hygienists plus all necessary equipment and procedures to avoid even small personal exposure to the reaction mixture, workup and byproduct streams.

Chloromethylation is an electrophilic aromatic substitution initiated by a source of formaldehyde, trioxane in this case, an acid and a chloride source, HCl in this case.

The inventors screened hexadecyl trimethyl ammonium bromide, a variety of tetrabutylammonium salts, and a crown ether as the “phase-transfer catalysts.” As shown in the figure, hexadecyl trimethyl ammonium bromide gave 96% yield under the conditions shown. The tetrabutylammonium salts bromide, fluoride, nitrate, hexafluorophosphate and perchlorate gave 70%-83% yield. Two crown ethers gave 63%-67% yield. Benzyl trimethyl ammonium chloride gave 70% yield.

Since hexadecyl trimethyl ammonium bromide gave 96% yield and the much smaller benzyl trimethyl ammonium chloride gave only 70% yield, we speculate that the preferred mechanism may be related to its surfactant properties given the classical head-and-tail structure for quat surfactants with one long alkyl chain. However, there is no organic liquid phase and no mention was made of emulsions. The inventors state that they used vigorous stirring at 1500 rpm which suggests that enhanced interfacial interactions are useful. Based on the very vigorous agitation and the high effectiveness of the surfactant hexadecyl trimethyl ammonium chloride, we speculate that an interfacial mechanism may be more valid for this application than a true phase-transfer mechanism.

There is an aqueous phase and the product is a solid that is filtered from the reaction mixture. The inventors note that the process requires no further purification other than crystallization, washing the solid product with ethanol and drying.

No mention was made in the procedures or body of the patent of any safety precautions to protect against exposure to the potentially formation of bischloromethylmethyl ether. While we understand that there is no requirement to do so in a patent, we would like to emphasize again that it is imperative to perform a thorough and professionally competent hazard operations analysis and take all possible safety precautions before considering any attempt to repeat these reaction conditions even on a small scale.

When your company is considering any potential phase-transfer catalysis application, contact Marc Halpern of PTC Organics to benefit from highly specialized expertise in industrial phase-transfer catalysis.